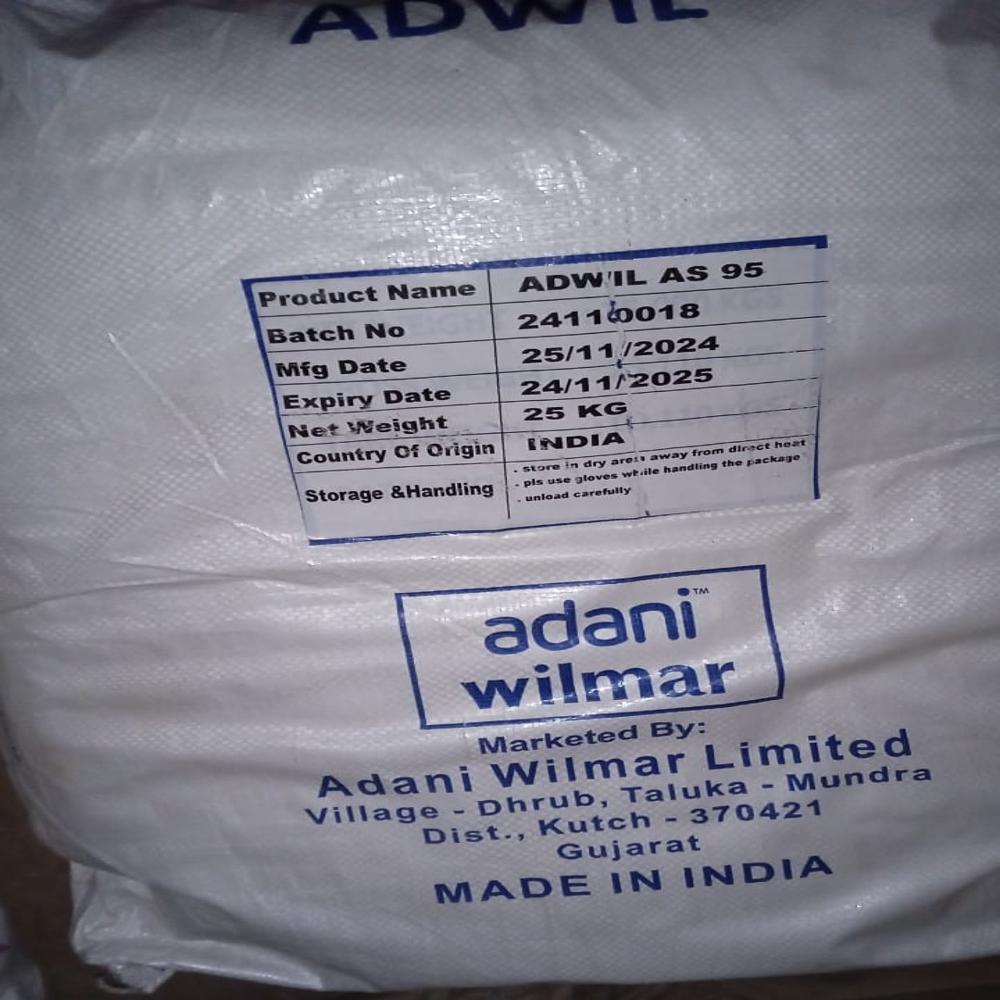

Adwil AS95

Adwil AS95 Specification

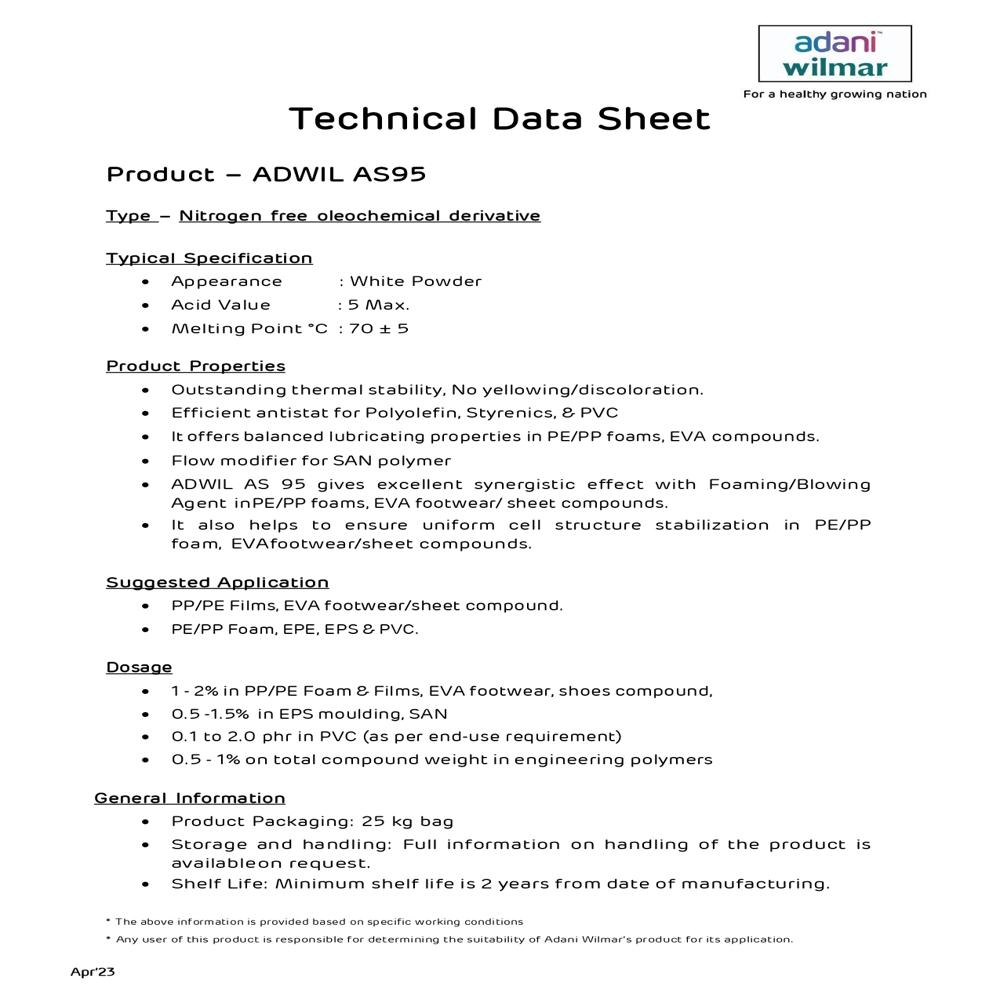

- Appearance

- Appearance : White Powder

- Usage

- Dosage 1 - 2% in PP/PE Foam & Films, EVA footwear, shoes compound, 0.5 -1.5% in EPS moulding, SAN 0.1 to 2.0 phr in PVC (as per end-use requirement) 0.5 - 1% on total compound weight in engineering polymers

- Physical Form

- Powder

- Properties

- Product Properties Outstanding thermal stability, No yellowing/discoloration. Efficient antistat for Polyolefin, Styrenics, & PVC It offers balanced lubricating properties in PE/PP foams, EVA compounds. Flow modifier for SAN polymer ADWIL AS 95 gives excellent synergistic effect with Foaming/Blowing Agent in PE/PP foams, EVA footwear/ sheet compounds. It also helps to ensure uniform cell structure stabilization in PE/PP foam, EVA footwear/sheet compounds.

- Melting Point

- Melting Point C : 70 5

- Application

- Industrial

- Shelf Life

- 2 Years

Adwil AS95 Trade Information

- Minimum Order Quantity

- 1000 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Sample Available

- No

- Packaging Details

- Product Packaging: 25 kg bag

About Adwil AS95

- Outstanding thermal stability, No yellowing/discoloration.

- Efficient antistat for Polyolefin, Styrenics, & PVC

- It offers balanced lubricating properties in PE/PP foams, EVA compounds.

- Flow modifier for SAN polymer

- ADWIL AS 95 gives excellent synergistic effect with Foaming/Blowing Agent in PE/PP foams, EVA footwear/ sheet compounds.

- It also helps to ensure uniform cell structure stabilization in PE/PP foam, EVA footwear/sheet compounds.

- PP/PE Films, EVA footwear/sheet compound.

- PE/PP Foam, EPE, EPS & PVC.

- 1 - 2% in PP/PE Foam & Films, EVA footwear, shoes compound,

- 0.5 -1.5% in EPS moulding, SAN

- 0.1 to 2.0 phr in PVC (as per end-use requirement)

- 0.5 - 1% on total compound weight in engineering polymers

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polymer Additives Category

Adwil Lube 53

Minimum Order Quantity : 1000 Kilograms

Application : Industrial

Appearance : Appearance : White Powder

Physical Form : Powder

Properties : Product Properties Internal lubricant which has very high compatibility with PVC. Excellent dimension stability Low die swell No adverse effect on mechanical properties Excellent thermal stability

Product Type : Appearance : White Powder

ADWIL LUBE OL4

Minimum Order Quantity : 1000 Kilograms

Application : Industrial

Appearance : Appearance : Clear Liquid

Physical Form : Liquid

Properties : Product Properties Balanced Internal and external lubricating effect. Reduce sticking problem Improve surface finish and gloss Doesn t affect clarity of the films

Product Type : Appearance : Clear Liquid

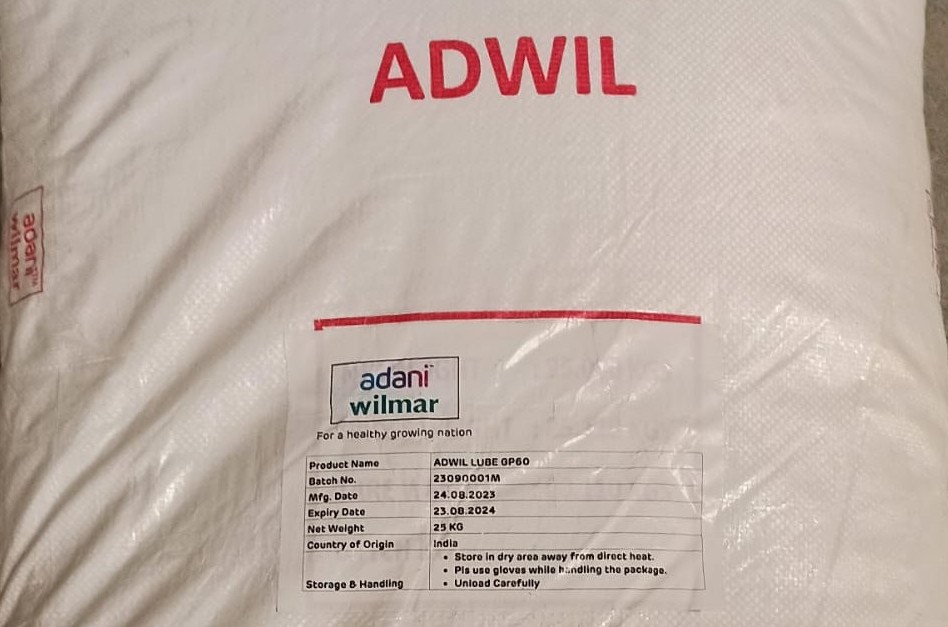

ADWIL LUBE GP60

Minimum Order Quantity : 2500 Kilograms

Application : Industrial

Appearance : Slight Yellow Flakes/White Powder

Physical Form : Powder

Properties : Properties: 1) ADWIL LUBE GP 60 it can be used to produce all kinds of PVC products as an internal lubricant. 2) ADWIL LUBE GP 60 has the excellent dispersion and provide good transparency effect. 3) It is white or slight yellow flakes or white powder, and it is nontoxic and odorless. 4) Improve the melt flowability during processing. 5) Provide lubricating property without lowering meltstrength.

Product Type : Slight Yellow Flakes/White Powder

ADWIL AID-43

Minimum Order Quantity : 100 Kilograms

Application : Industrial

Appearance : Tan powder/Beads

Physical Form : Powder

Properties : Product Properties ADWIL AID 43 is helps to ensure the uniform dispersion of fillers/pigment and other additive in the compound. It also ensures excellent cell structure in EVA compound stabilization along good releasing property. Particle of ADWIL AID 43 get activated when heat and shear is applied and thus creating a network of fiber like structure between polymer and filler. Helps to lower the viscosity and improved the flow at processing temperature. Reduce batch to batch variation. It has excellent thermal stability. Improves the surface finish and gloss.

Product Type : Polymer

GST : 27AAKFV1738Q1ZD

|

V. K. INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry