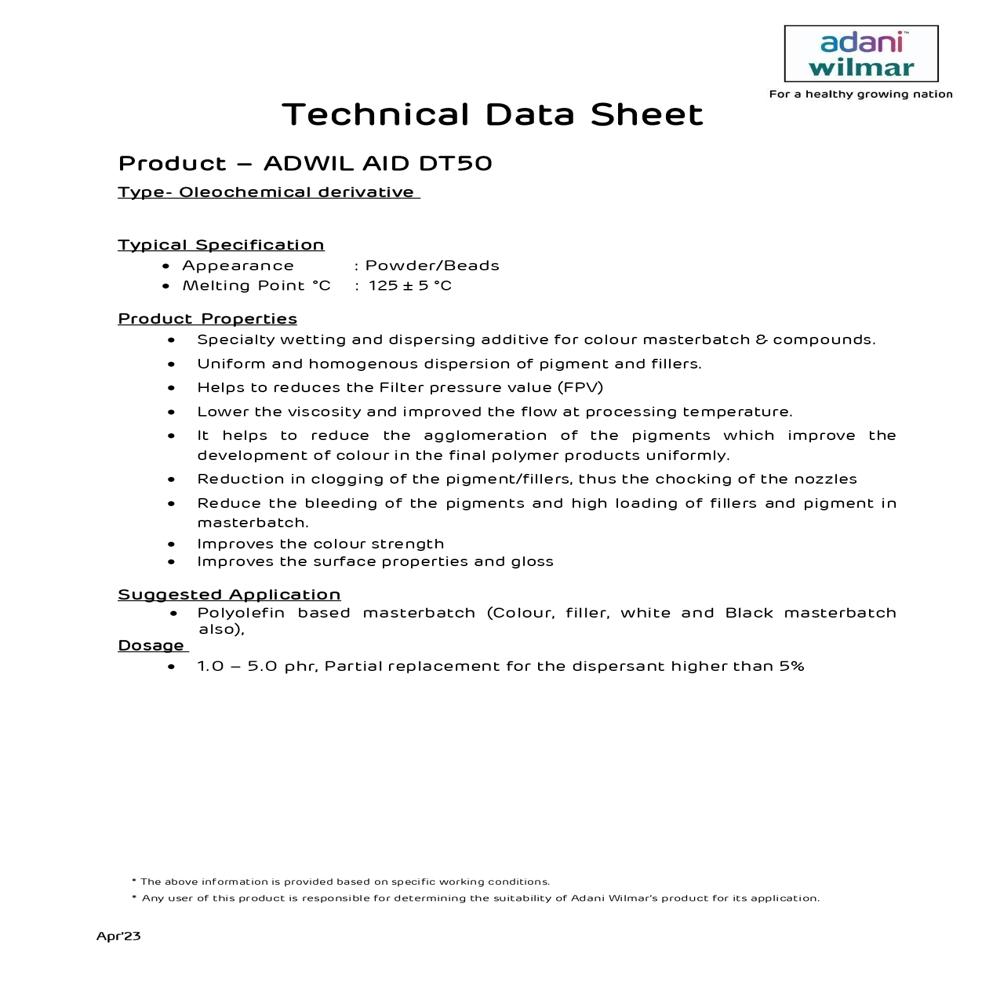

ADWIL AID DT50

ADWIL AID DT50 Specification

- Physical Form

- Powder

- Appearance

- Appearance : Powder/Beads

- Application

- Industrial

- Melting Point

- Melting Point C : 125 5 C

- Product Type

- Appearance : Powder/Beads

- Properties

- Product Properties Specialty wetting and dispersing additive for colour masterbatch & compounds. Uniform and homogenous dispersion of pigment and fillers. Helps to reduces the Filter pressure value (FPV) Lower the viscosity and improved the flow at processing temperature. It helps to reduce the agglomeration of the pigments which improve the development of colour in the final polymer products uniformly. Reduction in clogging of the pigment/fillers, thus the chocking of the nozzles Reduce the bleeding of the pigments and high loading of fillers and pigment in masterbatch. Improves the colour strength Improves the surface properties and gloss

- Usage

- Suggested Application Polyolefin based masterbatch (Colour, filler, white and Black masterbatch also), Dosage 1.0 5.0 phr, Partial replacement for the dispersant higher than 5%

ADWIL AID DT50 Trade Information

- Minimum Order Quantity

- 2500 Kilograms

- Packaging Details

- 25 Kgs Bag

- Certifications

- Suggested Application Polyolefin based masterbatch (Colour, filler, white and Black masterbatch also),

About ADWIL AID DT50

- Specialty wetting and dispersing additive for colour masterbatch & compounds.

- Uniform and homogenous dispersion of pigment and fillers.

- Helps to reduces the Filter pressure value (FPV)

- Lower the viscosity and improved the flow at processing temperature. It helps to reduce the agglomeration of the pigments which improve the development of colour in the final polymer products uniformly.

- Reduction in clogging of the pigment/fillers, thus the chocking of the nozzles

- Reduce the bleeding of the pigments and high loading of fillers and pigment in masterbatch.

- Improves the colour strength

- Improves the surface properties and gloss

- Polyolefin based masterbatch (Colour, filler, white and Black masterbatch also),

- 1.0 5.0 phr, Partial replacement for the dispersant higher than 5%

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Polymer Additives Category

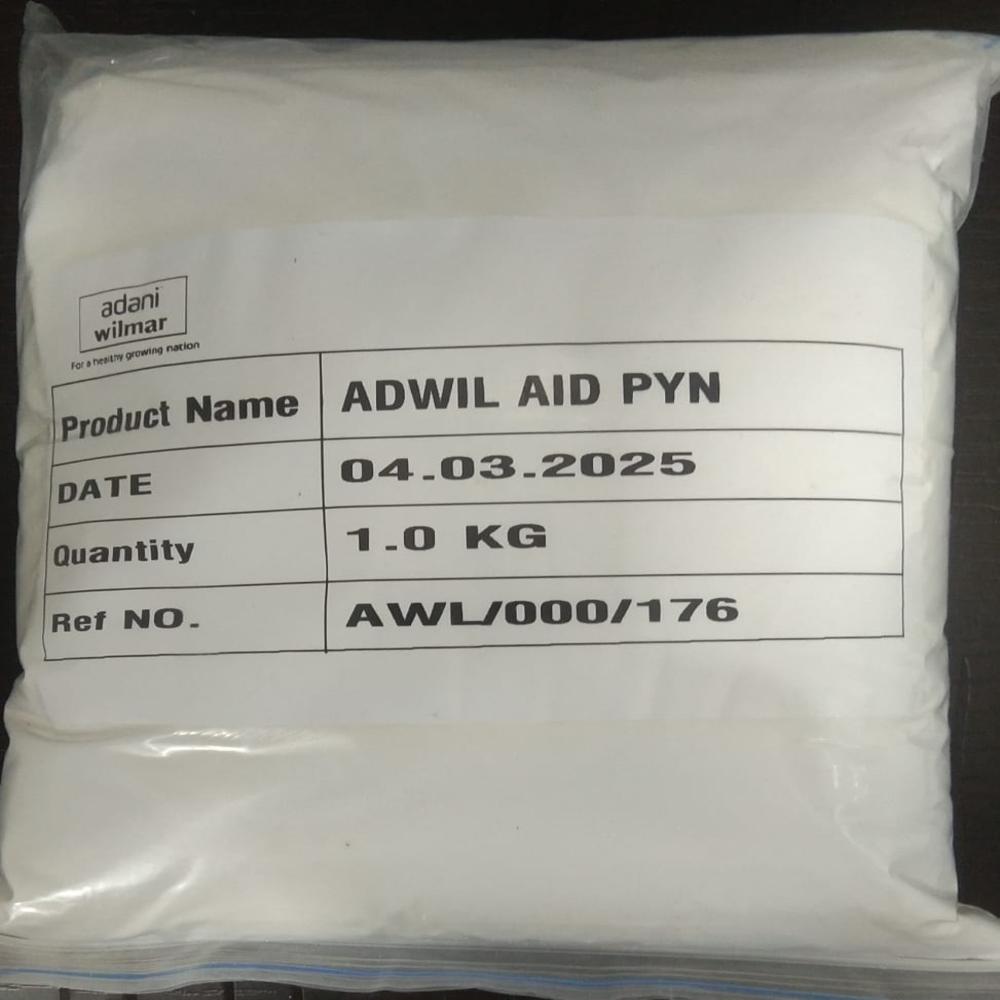

ADWIL AID-PYN

Minimum Order Quantity : 100 Kilograms

Properties : Product Properties ADWIL AIDPYN is specialty additive developed for antifibrillation masterbatch to reduce water carry over on tape line during highspeed operation. Homogeneous dispersion of fillers and pigments Improves the strength of the tape It helps to reduce the viscosity and improved the flow at processing temp. Improved the surface finish and gloss of the product

Usage : Suggested Application It is suitable for highly filled CaCo3 and Talc based Polyolefin compounds Reduces water carry over on tape line during highspeed operation Colour masterbatch (Polyolefin base) Dosage O.5 1.5 % for fillerbased PE/PP compound.

Appearance : Tan white Powder/bead

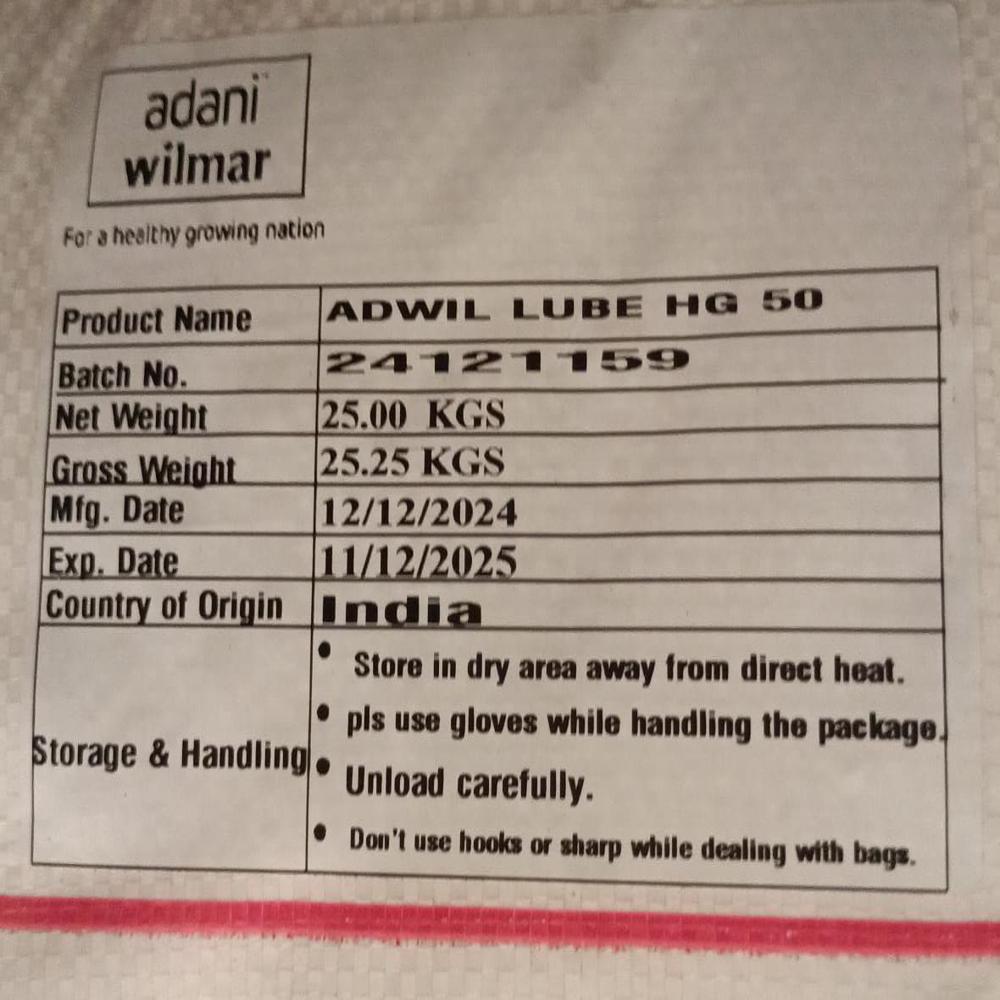

Adwil HG 50

Minimum Order Quantity : 2500 Kilograms

Properties : Product Properties : Internal lubricant Excellent flow improver Also used in fitting/molded application. Also suitable for transparent products Improves the surfaces gloss.

Usage : Suggested Application Rigid PVC Pipes, profile, and conduits Rigid PVC fitting/moulding application Dosage Rigid PVC 0.6 1.5 Phr Soft PVC 0.5 1.0 Phr

Appearance : Appearance : Tan Powder

Product Type : Tan Powder

Physical Form : Powder

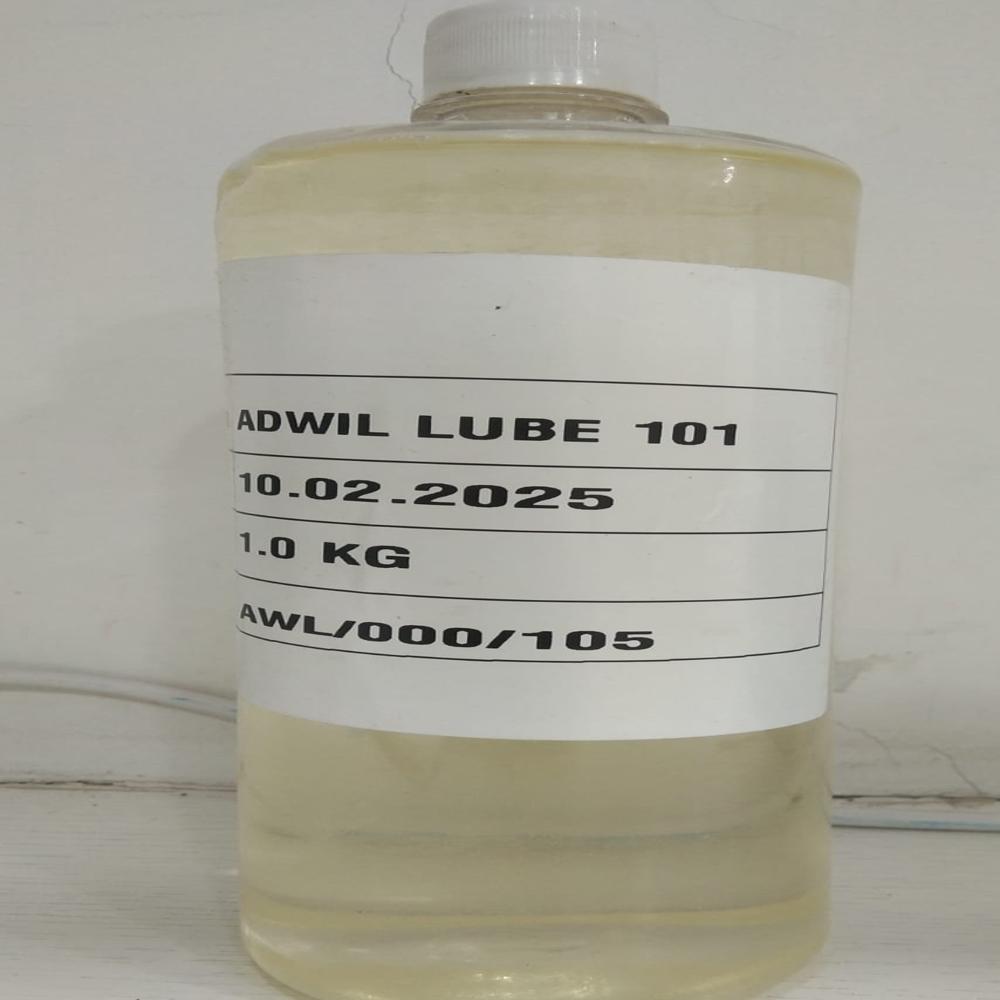

ADWIL LUBE 101 ink

Minimum Order Quantity : 200 Kilograms

Properties : Product Properties ADWIL LUBE 101 is an excellent wetting and dispersing agent. It helps to achieve desired dispersion of organic and Inorganic pigment. Increases the colour strength. Enhance Gloss and surface finish. Prevents flocculation of pigments

Usage : Dosage Generally, 0.25 to 0.8 % on weight of pigments is sufficient for rapid dispersibility.

Appearance : Appearance : Yellowish liquid

Product Type : Yellowish liquid

Physical Form : Liquid

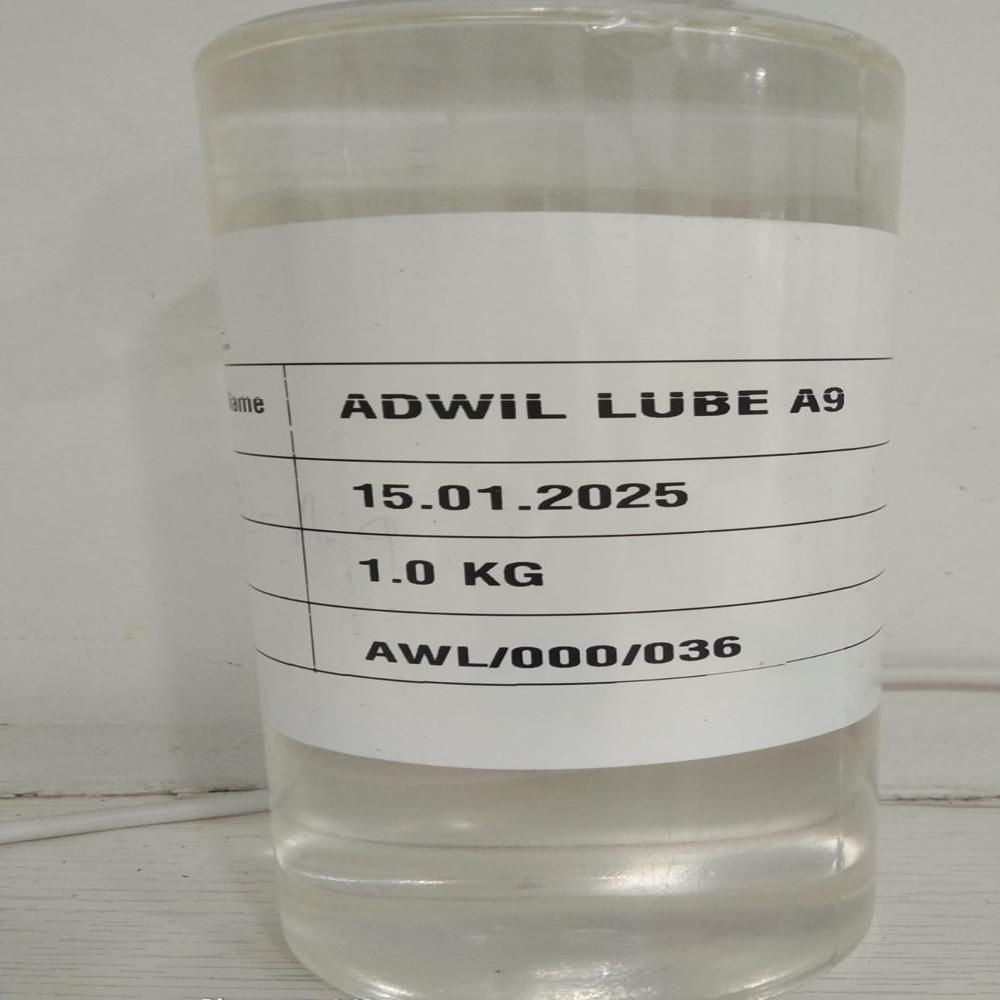

Adwil Lube A9

Minimum Order Quantity : 1000 Kilograms

Properties : Product Properties ADWIL LUBE A9 is secondary plasticizer for PVC i.e. it cannot be used as sole plasticizer. Internal lubricant and secondary plasticizer Suitable for use in transparent products Improves gloss and surface finish ADWIL LUBE A9 also helps in uniform dispersion of filler and suitable wetting and dispersing agent for filled Polyolefin/EVA compounds & masterbatch. Adhesive for drydyeing flakes Secondary plasticizer in PVC paste

Usage : Dosage 0.5 5.0 phr in PVC application 0.5 1% as wetting and dispersing agent

Appearance : Appearance : Clear Liquid

Product Type : Clear Liquid

Physical Form : Liquid

GST : 27AAKFV1738Q1ZD

|

V. K. INTERNATIONAL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry